ON-BOARD COMPUTING AT THE SERVICE OF THE PEOPLE

February 18, 2022

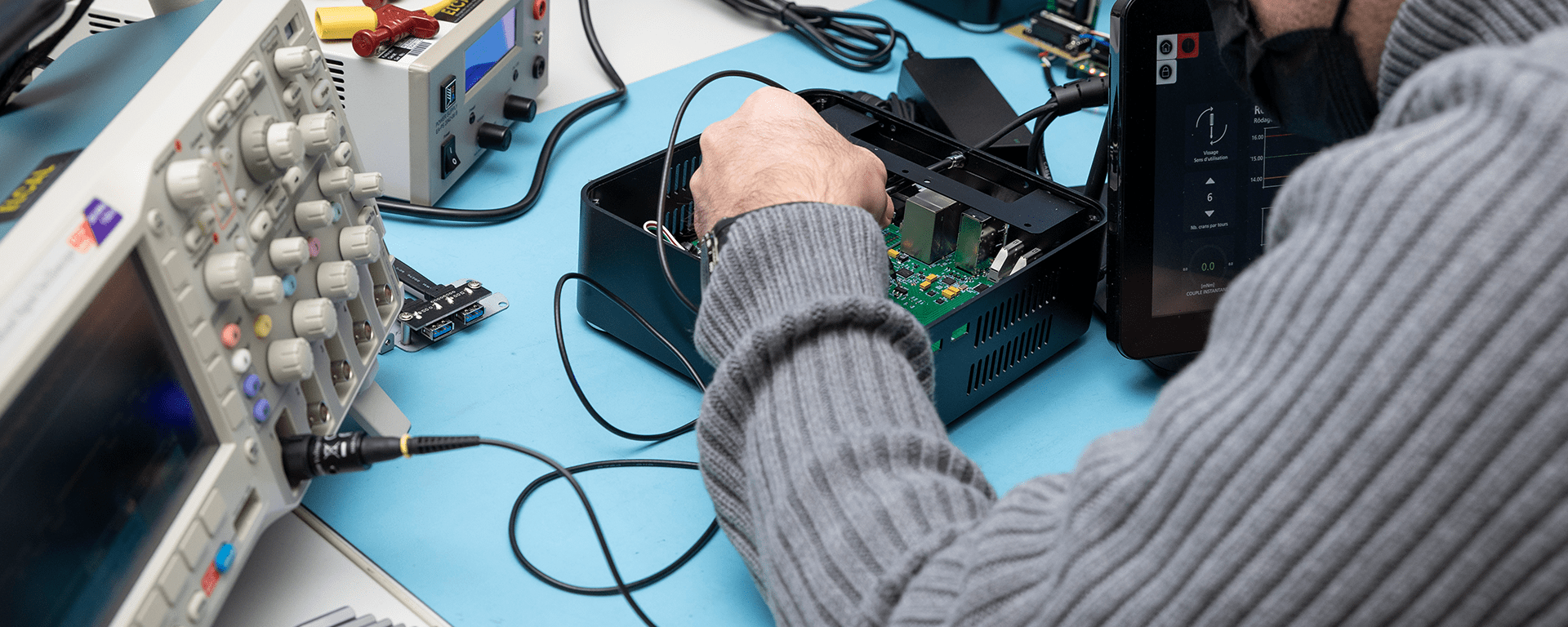

THE RISE OF MECHATRONICS

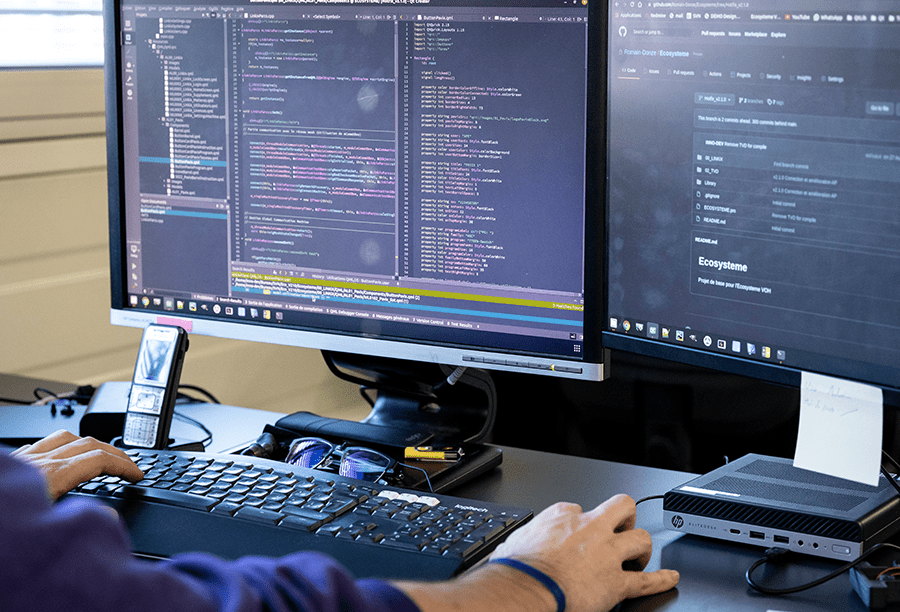

“It is necessary to contextualize each project,” says Richard Vaucher, “and to question the relevance of what we are creating, for whom and why. These questions must be reflected in each stage of the development, with the final vision being a precise response to the client’s expectations.”

” ENHANCE THE HUMAN GESTURE “

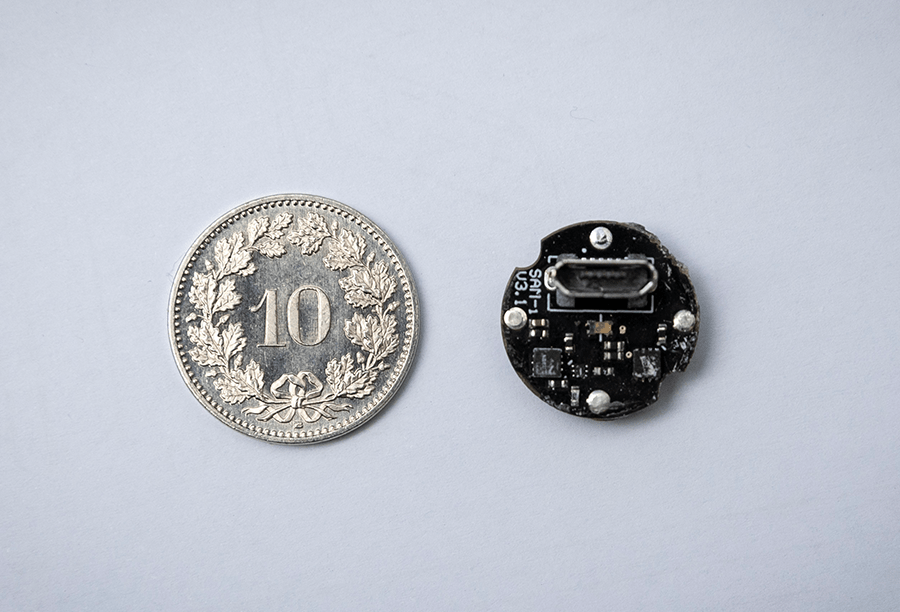

With embedded computing in VOH products, users have complete traceability data “captured” in a discreet manner. “Clearly, the best electronics are those that are invisible,” says Bastien Paratte. However, it is important not to limit the advantages of the products to discretion and accessibility of the data; the original function remains the ultimate goal of a VOH product.

“It does not replace the human being, but rather enhances the skills that make Swiss watchmaking so valuable,” enthusiastically states Richard Vaucher. In fact, enhancing the watchmaker’s skills is the true leitmotiv of the company’s employees. Each member of the team has a precise role to play, coordinating and optimizing the realization of each product, from information technology to assembly, including ergonomics, always with the constant concern of designing quality products with a reliability level deserving of VOH’s ambition.